You may think that if you’ve seen one draft beer faucet, you’ve seen them all. Wrong. Beer faucets come in a variety of styles and materials depending on what you are going to be pouring from them.

Your faucet is an integral part of your draft beer dispensing system, and like most other parts of your system, you’ve got plenty of options to choose from to help meet your pouring needs as precisely as possible.

There are a number of things to consider when choosing the right draft beer faucets for your system. Let’s find one that will work best for you.

Table of Contents

What Is a Draft Beer Faucet?

Before we start talking about all of the options available for your draft beer faucet, let’s talk about what exactly a beer faucet is.

In the simplest terms, your draft beer faucet attaches directly to the shank or tower of your dispensing system. It is the last part of your system that touches the beer before it ends up in your glass. As such, it plays a crucial role in dispensing your brew by helping to direct the flow. Without a faucet, you’d have an uncontrollable cascade of beer that would be nearly impossible to get into a glass.

But not all pouring situations are created equal. For that reason, there are myriad faucet types, designs, and materials.

Types of Beer Faucets

The type of faucet you use depends on what kind of beer you are planning on pouring and the type of draft system you have.

Standard Draft Beer Faucets

Standard faucets are perfect for pouring any domestic draft beer, whether you have just a single tap kegerator or a commercial establishment with a wall of taps. You can purchase one and install it without having to buy any additional equipment for your draft system. They connect directly to the shank or draft beer tower and include a ⅜-inch threaded lever that fits virtually any tap handle for easy operation.

Standard faucets are available in a variety of materials and finishes, including chrome-plated or polished brass and stainless steel. Since they are used so frequently, replacement parts are very easy to find in case they need to be repaired.

Rear Sealing Faucets

Most draft faucets you'll find are rear sealing faucets. They control the flow of beer from the back of the faucet as the lever moves a valve shaft inside the faucet body which opens and closes the rear seal. The vents inside the shaft slow the flow of beer to provide a nice, smooth pour. These faucets are easy to disassemble for cleaning purposes. Rear sealing faucets are a cost-effective option versus a forward sealing faucet.

Forward Sealing Faucets

Forward sealing or ventless draft beer faucet differs from traditional rear sealing faucets in that they greatly reduce the amount of beer that is exposed to oxygen. Instead of a valve shaft controlling the flow at the back of the faucet, the flow is controlled at the front end. This means less beer gets trapped inside the flat area of the faucet body, which keeps your tap handle from sticking and is less susceptible to bacteria and mold growth. Forward-sealing faucets also have fewer internal parts, which means you will spend less time and money on repairing or replacing faucets.

Forward sealing faucets tend to pour more quickly than rear sealing ones because the beer does not have to travel through any vents. This creates extra turbulence, which may lead to foamy beer. To help this, many manufacturers offer a flow control model to help consumers slow their pour down.

European Draft Beer Faucets

European beer faucets operate similarly to their standard American counterparts with a few exceptions, the biggest difference being the longer and skinnier spout. The narrow spout reduces the amount of foam you get when pouring, which makes it great for filling growlers and pitchers.

The caveat with European faucets is that they have different threads or a shorter shank than standard faucets, which makes them incompatible with many draft systems in America, especially kegerators.

Thankfully you can find extended spout faucets that are made to fit standard shanks and towers.

Nitrogen Stout Draft Beer Faucets

If you want to serve up Guinness, Boddington’s, Murphy’s, or any other brew that requires nitrogen or mixed gas for dispensing, you’ll need a special Nitrogen Stout Beer Faucet.

The long, narrow design of a stout faucet pairs with a special restrictor disc inside to help power the beer quickly through the faucet, creating the cascading, thick head typically associated with nitro brews. For maximum versatility, you can easily remove the restrictor disc and use this faucet to dispense “regular” CO2-powered beers.

Extended Spout Draft Beer Faucets

Extended spout faucets, help you control your pour by creating less distance (and thus less loose foam) between the faucet and the glass, pitcher, or growler you’re trying to fill. The extended spout is also ideal for dispensing wine because the limited drop helps prevent over-oxidation while pouring.

Czech Side Pull Pilsner Draft Beer Faucets

While the ultimate goal of pouring a pint of beer in America is to keep the amount of foam to a minimum, there are parts of the world where a mug of foam would not be angrily slid back to the bartender when presented.

A side pull draft beer faucet or Czech beer faucet has a trio of micro-filters to control the flow of beer to create a creamy head, which is the traditional way of enjoying a Czech pilsner. You submerge the spout in the mug to create a silky, sweet head of foam. You can learn more about the different styles of pours you can do with our guide to Czech side pull faucets.

Specialty Draft Beer Faucet Features

Self-Closing Faucets

A standard self-closing faucet does exactly what its name promises: it closes itself! The rest of the construction is the same as a standard faucet, but instead of having to manually push it closed, it will return to the closed position when you take your hand off the lever. This is a great option to help conserve beer and prevent accidental spills.

Creamer Faucets

A standard creamer faucet generally has the same construction and finish options as a standard faucet, but it adds a greatly enhanced level of control over the creamy head of your pint. The lever is specially constructed to be pulled forward or pushed back. When you pull it forward, beer flows freely, but when you push it back you can deliver as much creamy foam as desired to add to the aesthetics and taste of your brew.

Flow Control Faucets

If you’re going to be pouring sampler glasses, using frosty mugs, or frequently changing your keg to vastly different styles of brew, a flow control faucet will help manage your pour with ease. These faucets feature a special lever on the side that restricts the flow so that you don’t end up with a foamed-over glass.

Flow control faucets are required equipment if you are going to be serving carbonated cocktails on tap. Carbonated cocktails are dispensed at very high pressure and flow control faucets offer the necessary restriction to control beverage flow. Flow control faucets are also recommended for dispensing kombucha. Though not absolutely necessary, it’s recommended to help counteract foaming issues that might arise with kombucha’s ambiguous carbonation level.

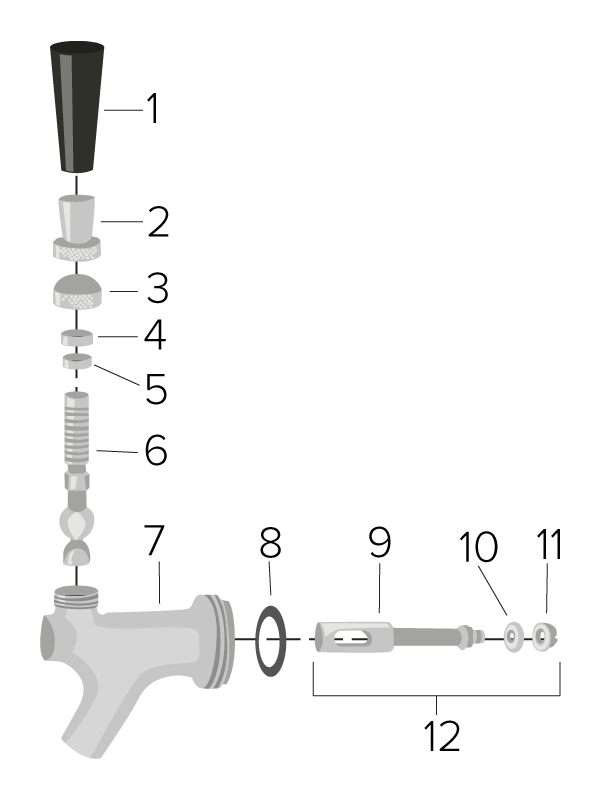

Parts of a Draft Beer Faucet

Draft beer faucets look pretty straightforward, and in many ways they are. But they are also made up of a slew of smaller parts, and each one is essential to the assembly’s proper function. Over time, these smaller parts wear and tear, which can lead to leaks and other malfunctions. When this happens, it’s a good idea to have an understanding of how the parts of your faucet fit together so you can replace them easily. With a little know-how, you can also refurbish an old beer faucet or build one from scratch. That’s where a beer faucet diagram comes in handy. The following is a breakdown of a standard rear sealing draft faucet.

- Tap Handle: The handle that connects to and controls the lever. It’s the part you pull forward to initiate beer dispensing. It can be replaced with a branded, novelty, or custom handle.

- Lever Collar: A small piece of metal hardware that holds the faucet lever assembly secure. It also helps align a branded tap marker so that it is forward facing and visible to users and consumers.

- Lever Bonnet: When paired with a friction washer, it creates the friction necessary to open and close the beer faucet.

- Friction Washer: This friction created by this small but significant faucet part prevents the lever from sliding loosely during use.

- Ball Washer: It’s the first piece that goes onto the faucet lever, where it seals the faucet to prevent spray. If the ball washer looks dingy, dirty, or moldy, it’s a sign of infection.

- Lever: The metal piece that controls the opening and closing of the internal valve that controls the flow of beer through the faucet body. When you pull the lever forward by way of the tap handle, it pushes the shaft backwards, which opens the valve. Levers are threaded to attach to the faucet knob/tap handle.

- Faucet Body: The largest single component of your beer faucet, it directs the flow of beer through the spout to your waiting glass. Faucets come in different finishes. We recommend stainless steel to ensure off, metallic flavors don’t taint your beer.

- Faucet Body Gasket: Seats the faucet to the beer shank for a leak-free connection.

- Shaft: Connected to the lever, it is pushed forward or pulled back to control the flow of fluid.

- Shaft Seat/Seating Washer: Seals the valve to stop the flow of beer. As it wears with age, you may experience a small, slow leak.

- Shaft Nut: The metal fastener that secures the shaft seat to the shaft.

- Faucet Shaft Assembly: The term for the shaft, seat, and nut when referencing it as one unit.

Draft Beer Faucet Materials

Draft faucets are typically available in three types of finishes: chrome-plated, stainless steel and polished brass. While all three have different aesthetic qualities, there are some additional things to keep in mind when selecting the style you want to use.

Chrome Draft Beer Faucets

Chrome-plated brass faucets are the most common style of faucet you will find. The shiny chrome finish is visually appealing, and stands out behind any bar. They are more cost-effective and have the same function as stainless steel, but they don’t hold up well to the wear and tear of long-term continuous use.

After years of use and exposure to low-level acidity from both the beer itself and various cleaning agents, a traditional chrome-plated faucet may begin to corrode and impart unwelcome flavors to your brew.

If you are building a kegerator for your home or a draft system that won’t receive a high-level of use, then chrome-plated faucets are still a viable option for you. Just be sure to monitor the level of wear over time.

Stainless Steel Draft Beer Faucets

Stainless steel faucets are an upgrade over the standard option. The added value of having a sturdy stainless steel faucet that will last for many years behind your bar balances the trade-off of the premium cost.

Since stainless steel is less susceptible to corrosion it makes it a much more sanitary option because it is much more resistant to the formation of bacteria. For that reason, stainless steel is a must if you want to dispense wine on tap, coffee on tap, kombucha on tap or cocktails on tap because the acidity in these beverages will almost immediately corrode the finish of a plated-brass faucet and render whatever winds up in your glass undrinkable.

Polished Brass Faucets

If you crave the look of polished brass for your faucets, then you do have options. A polished brass draft faucet offers the same affordability and functionality as its chrome-plated counterpart. You can also get a stainless steel faucet with a tarnish free brass finish that provides the look of brass on the outside, but with the durability of stainless steel on the inside.

Best Draft Beer Faucets

There are a variety of draft beer faucets on the market made from the different materials we’ve covered in this guide. When selecting faucets for our draft system here at KegWorks, we chose stainless steel, forward sealing draft faucets. Stainless steel faucets are the sturdiest and longest-lasting faucet money can buy, and work with a variety of beverages. The forward sealing design is a more sanitary option as they leave little or no beer inside the faucet body when you are finished pouring.

Perlick Premium Draft Beer Faucets

Any standard faucet will get beer from the keg to your glass, but when you get serious about your dispensing and want to take things to the next level, Perlick is the way to go.

At KegWorks, we proudly carry Perlick 600 series draft beer faucets. All of these faucets feature Perlick’s legendary engineering innovation, including a unique forward-sealing design that greatly reduces oxygen exposure, a clean-pouring vertical spout that prevents old beer from collecting in a flat area and attracting bacteria or other contaminants, and a revolutionary “floating ball lever” that eliminates sticking and ensures a positive seal.

Most of these faucets also feature premium 304 stainless steel construction that will last forever, without ever impacting the flavor of your brew. This makes Perlick a perfect option for dispensing coffee, wine, or cocktails as well.

Having a better understanding of draft beer faucets will allow you to make a more informed choice when setting up your kegerator or draft system. Be sure to check out KegWorks full selection of draft beer faucets to find the one right for you!

Tags:

Kegworks

Kegworks has been transforming hospitality spaces since 1998 with expertly crafted architectural metalwork and professional draft beer equipment, helping designers, architects, and bar professionals bring their visions to life.

Leave a Comment