Across the country and around the world, more and more bar, restaurants, wineries, and sports and music venues are switching from bottled wine service to wine on tap systems. And their reasoning is clear: quicker service of a better product at a cost savings.

If you’re wondering if wine on tap would make sense for your business, read on about the benefits and requirements of a wine-compatible draft system.

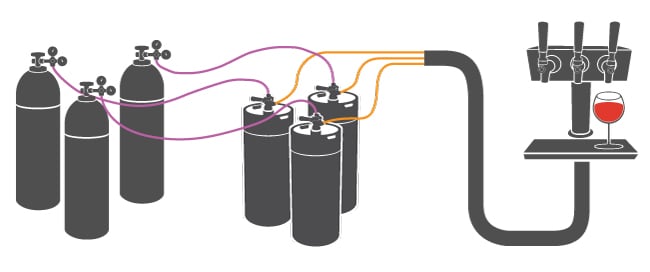

Wine on tap works in the same way as draft beer. With the pull of a tap handle, gas pressure forces the kegged liquid (in this case, wine), out of the keg valve, through food-safe plastic tubing to the faucet. From there, it dispenses into a ready glass.

With a bottled by-the-glass program, a certain percentage of the wine is wasted to oxidation or cork taint—two problems that kegged wine avoids. Moreover, kegged wines save producers the costs associated with commercial packaging and shipping, and some of those savings are passed on to you, the seller. In turn, you can pass some of the savings on to your customers, who will appreciate being served high-quality wine at a value price.

Assuming an average sixtel (5.16 gallons) of wine costs $250, and you sell 5-ounce pours at $8 a glass, the profit and ROI add up quickly.

Ounces Per Sixtel |

# 5oz Pours |

Keg Cost |

Cost per Glass |

| 661 | ~132 | $250 | ~$1.89 |

Sell Price per Glass |

Gross Profit |

ROI |

| $8 | $1056 | $806 |

Traditional wine service is a fairly time-consuming ritual. Your bartender or server must select the bottle, present it to the table, cut the foil, pull the cork, offer a sample, and then, finally, pour the glass.

With a wine on tap system, there are no corks to fuss with; wine can be quickly poured and served with a fraction of the effort. That helps increase efficiency and keeps service running smoothly.

Bar, restaurant, and winery patrons have been trained to expect options. They crave experiences and are constantly on the hunt for something new and exciting. Wine on tap allows for controlled pouring and nontraditional sized pours that are perfect for tasting rooms, tasting flights, or upselling someone with the aid of a sample.

Draft systems help ensure the integrity of wine in two ways. First, kegs are made of stainless steel and hold a larger volume of wine than glass bottles, making them far more resistant to temperature fluctuations during transport.

Second, unlike bottles of wine, which go bad within a day or two of opening due to the effects of oxygen, the inert gases of a draft system displace oxygen and prevent it from coming in contact with and spoiling wine. With wine on tap, you needn’t worry about going through an entire bottle before it goes bad, and you can rest assured the last glass in the keg will taste the same as the first.

Buying wine in reusable stainless steel kegs reduces the waste generated by commercial packaging, saving trash from landfills and reducing your establishment’s overall carbon footprint.

Generally speaking, wine on tap systems do not use the same gas as draft beer systems. The CO2 used for beer would eventually carbonate the wine. For still red and white wine, dispensing should be powered by 100% nitrogen or 100% argon. The exception is dedicated sparkling wine systems, which welcome carbonation. For sparkling wine, use 100% CO2.

There are two primary setup options:

Have questions about your unique program or setup? Give our draft specialists a call at 1.888.415.2803 or fill out the form below.

Quick Turnaround Times

60-Day Return Policy

Through SSL Protection

Dedicated Sales Rep