Find out how to properly disassemble and clean a keg coupler as part of regular maintenance of your kegerator or draft beer system.

We can never stress enough the importance of cleaning your draft beer components in addition to regularly cleaning your beer lines. It’s not hard for bacteria to grow in places inside your draft system that a standard beer line cleaning won’t reach. Your keg coupler is one part that you should pay attention to regularly cleaning as an essential step to having a sanitary kegerator or draft system.

How often should you clean your keg coupler?

We recommend giving your coupler a deep clean every other time you clean your beer lines.

What you’ll need to clean your draft beer coupler

- Rubber or latex gloves

- Safety glasses

- Cleaning solution (we recommend our Power Punch cleaner)

- Crescent wrench or pliers

- Small brush

- Replacement O-rings and seals

How to clean a keg coupler

Note: We are cleaning a D-System Sankey coupler for the purposes of these instructions. The disassembly and assembly process will be different if you use a different keg coupler style.

Step 1: Disconnect the keg coupler

Turn off your CO2 or nitrogen and disconnect the coupler from the keg. Remove the air line from the coupler, set aside the Thomas valve and retainer, and then remove the beer line.

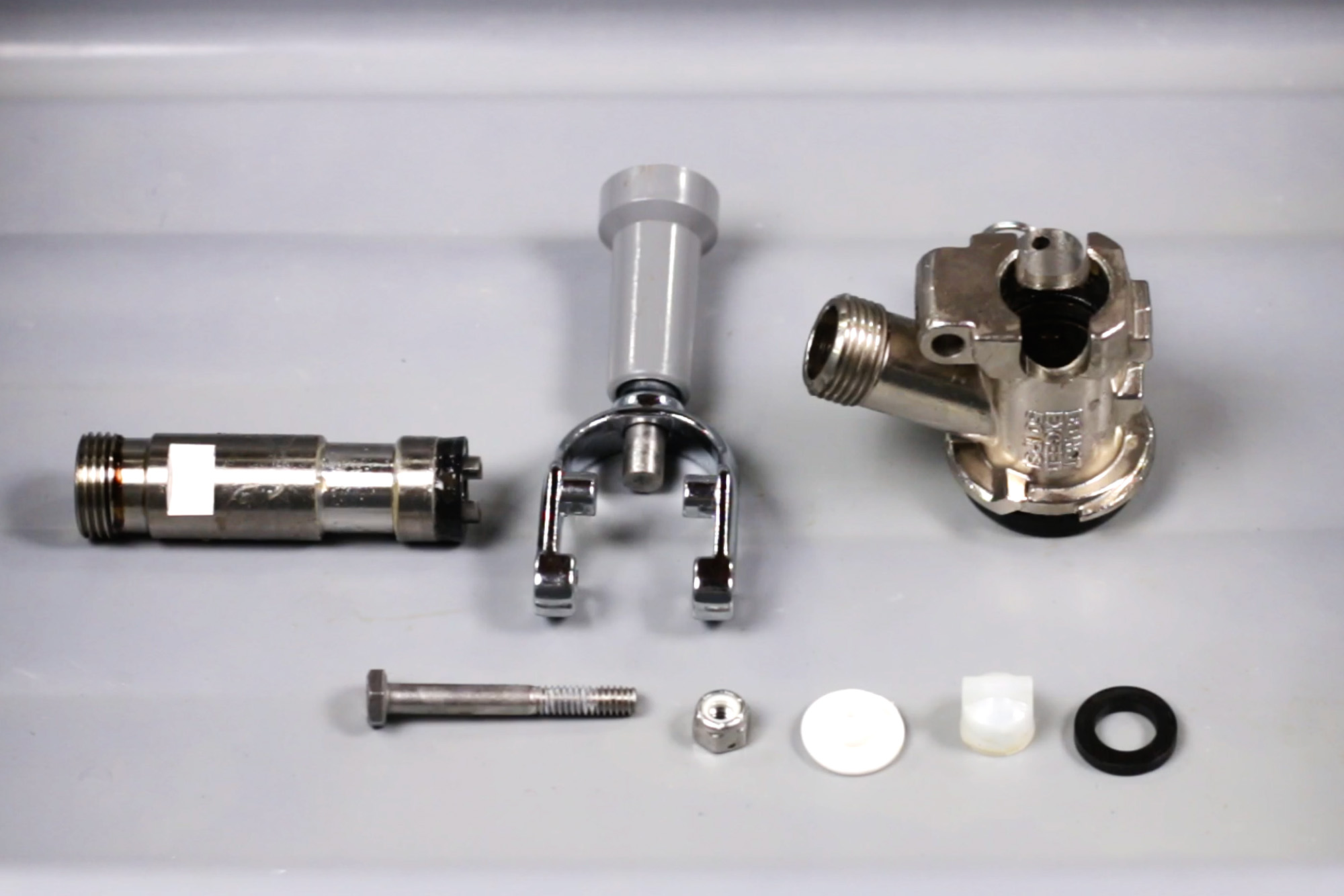

Step 2: Disassemble the coupler

Start disassembling the coupler by removing the hinge pin, the lever handle, and the probe. Place all of the parts in a small container or bucket to wash them.

Step 3: Washing the coupler parts

Fill the container or bucket with warm water and Power Punch cleaning solution. Scrub all of the parts with the brush, making sure to get inside the body and probe. Rinse all of the parts thoroughly once they are cleaned.

Pro tip: Now is a good time to check that all of your seals are in good condition and replace any that aren’t.

Step 4: Reassemble the coupler

Start putting your coupler back together by sliding the probe into the body, and then slide the handle over the probe and align the hinge pin holes. Insert the hinge pin and tighten the nut, making sure to not overtighten. (Note: the hinge pin is supposed to turn freely). Finally, replace the Thomas valve and retainer.

Once your coupler is reassembled, you can reattach your air and beer lines and hook your coupler back up to your keg.

With your keg coupler freshly cleaned, you can get back to pouring copious amounts of delicious draft beer and know its quality won’t be affected by a dirty draft component.

Tags:

Kegworks

Kegworks has been transforming hospitality spaces since 1998 with expertly crafted architectural metalwork and professional draft beer equipment, helping designers, architects, and bar professionals bring their visions to life.

Leave a Comment