For many bar and restaurant owners, a draft beer system is the lifeblood of their business. Draft beer is typically one of the most profitable products served in hospitality settings. But there’s a caveat - that’s only as long as it is operating correctly. Once you run into problems, you start throwing money down the drain, one pint at a time.

There are three things that are vital to a well-balanced draft beer system: temperature, pressure, and restriction. Out of the three, temperature is, by far, the one that contributes the most to draft beer problems. The good news is, temperature is easy to monitor and control. Below you’ll find what to look for to see if you have a temperature issue, how to monitor and troubleshoot temperature issues, and what you can do to prevent them altogether.

What’s the Ideal Temperature?

There are three words that are often used in large beer company marketing, “Ice Cold Beer.” While it sounds refreshing, and many domestic beers are designed to taste better at colder temps, this marketing phrase is misleading.

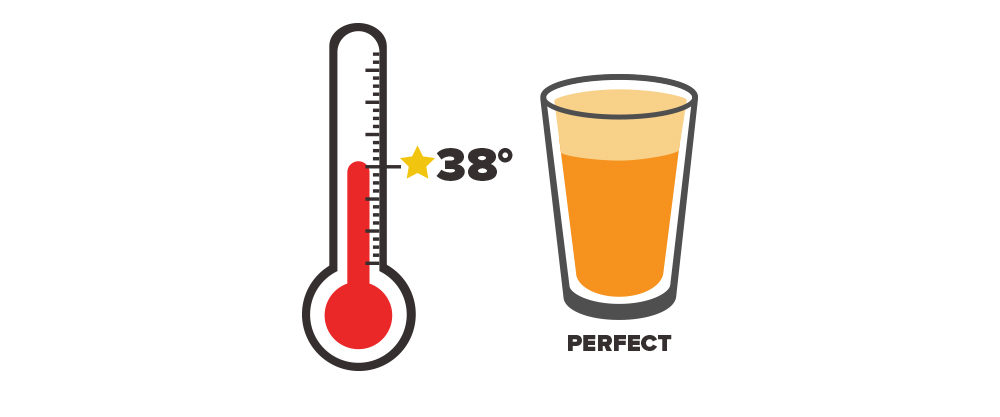

The standard temperature range for draft beer in the United States is between 36 and 40 degrees (a bit above “ice cold”). But because you are working to eliminate issues and maintain a perfectly balanced system, it is recommended that you shoot for a target temperature of 38 degrees and not a range. Hitting a target temperature of 38 degrees allows draft systems to perform at their best for the different beers that may be on tap. This means you want the beer at 38 degrees from keg to the point of dispense.

What Happens if Beer Gets Too Cold?

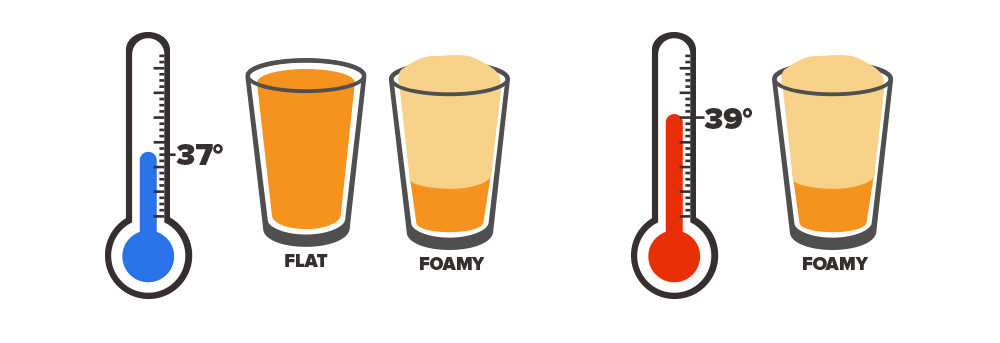

When your draft beer gets too cold, you may run into a couple of issues. First, CO2 is more soluble in cold beer, which means more carbonation stays in the beer even after it is served. This has the effect of making a beer taste flat, which can make for unsatisfied customers. It can also lead to glass overfilling, which equates to less profit. Moreover, if the beer is sitting too cold in the keg for too long, and the pressure is still set for your target 38 degrees, you are going to get wild foaming when you go to dispense. Wild foam = lost profit = worst case scenario for a draft beer system.

What Happens if The Beer Gets Too Warm?

This seems to be a more common problem in commercial draft systems—either due to temperature fluctuations or poorly installed systems that don’t account for distance from storage to dispense. When beer begins to go over 38 degrees, even by as little as half a degree, the CO2 begins to come out of solution. This creates major foaming issues. Warm temperatures also affect the appearance and taste of the beer. All of these are problems that will lead to a loss in profits and possibly future business from customers.

Getting a New Keg Ready to Serve

Kegs are large canisters of liquid, and they can take awhile to fully cool down to serving temperature. In fact, it can take a keg three to four times as long to chill as it takes to warm up, according to the Brewer’s Association Draught Beer Quality Manual. While you may want to immediately tap that fresh keg, it is best to wait. Allow the keg to sit in the refrigerator for 24 hours, with the temperature set between 34 and 38 degrees. This will ensure the beer in the keg is at the appropriate temperature for dispensing. Keep this in mind, and order your keg far enough ahead of time to account for the 24 hour acclimation process.

In addition, letting the keg sit for 24 hours allows it to settle. The delivery process will shake up a keg, no matter how careful the distributor is. And this can create foaming issues. Think of a keg like a giant can of beer, if you shake it around and open it right away you will have foam all over the place.

If possible, it would also behoove you to have a dedicated cooler for your kegs. Keeping kegs in a keg-specific walk-in cooler allows you to only worry about the temperature of the beer and not additional items in the cooler. A dedicated cooler also cuts down on unnecessary traffic , which can cause temperature fluctuations.

How to Monitor Liquid and Dispense Temperature

If you have a thermometer in your walk-in cooler, its reading tells you the temperature of the air in the cooler, not necessarily the temperature of the liquid in your keg. This isn’t a very accurate way to monitor beer temperature. So regardless of what your cooler thermometer reads, if your beer is coming out very foamy, it could, and most likely is, an issue with temperature.

There are a two temperature readings you are going to want to monitor in order to know both the liquid temperature in the keg and also the dispense temperature. Believe it or not, the temperature can change between the keg and the glass, depending on the draft setup you have. In order to take these temperatures you’ll need a liquid thermometer.

The first reading you should take is the liquid temperature. In order to do this, set a glass of water in your cooler. Give the water time to acclimate to the cooler temperature (about 24 hours) and stick a thermometer in it. This reading will be your liquid temperature. If it’s at 38 degrees (or close), you should be all set.

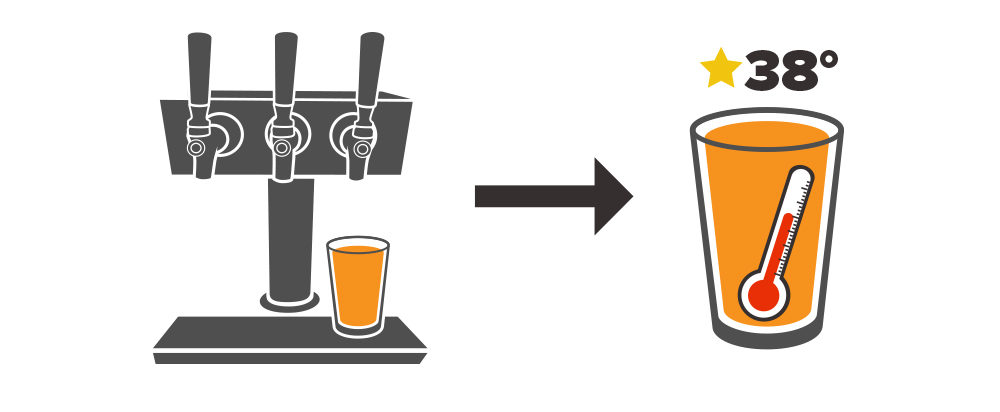

If you have a long draw system, you are also going to want to take a look at your dispense temperature. This is the temperature reading of the beer in the glass. To get a proper dispense temperature reading, pour a beer into a clean, room temperature glass and take the temperature of the beer immediately. If it is the same as the liquid temperature in the keg, then you know that you are maintaining the proper temperature from the keg to glass.

If you are still seeing foaming issues despite proper liquid and dispense temperatures, you can be confident that it isn’t temperature related and can move forward to troubleshooting other elements of your draft system.

If you do find a temperature differential between keg and glass, read on.

How to Guarantee Perfect Dispense Temperature

The best way to guarantee exact target temperature in your draft system is by installing a glycol system (for long draw setups, up to 450’ away from cooler). These chilling systems utilize trunk lines, cooled beer towers, and a glycol chiller. If you take the time and care to set up this type of system, you are going to eliminate a lot of hassle down the road, as well as ensure that you are maximizing the quality of beer and amount of profit you can achieve from each keg that comes through your doors. So what is a glycol chilling system? Great question.

Glycol systems have been around for awhile and are typically installed in a draft system where dispensing is 25’ to 450’ away from where the kegs are being stored. This type of system relies on a mixture of water and propylene glycol—a non-toxic, food-grade antifreeze—and trunk line, which is an insulated tube that houses a number of beer lines and glycol lines. The water/glycol mixture travels through the entire draw inside of the trunk line to keep the beer at the perfect target temperature from keg to glass.

Learn more about maintaining glycol cooling systems.

Leave a Comment