Whether you are pouring draft beer at home by way of a kegerator or in a commercial setting using a more complex setup, a beer regulator is a crucial piece of dispensing equipment.

What Are Draft Beer Regulators?

The contents of CO2 & nitrogen gas tanks are under extremely high pressure. The main function of any regulator is to lower that pressure to a safer, more usable level before the gas reaches the keg. The regulator is also responsible for maintaining the optimal carbonation level of the beer being dispensed.

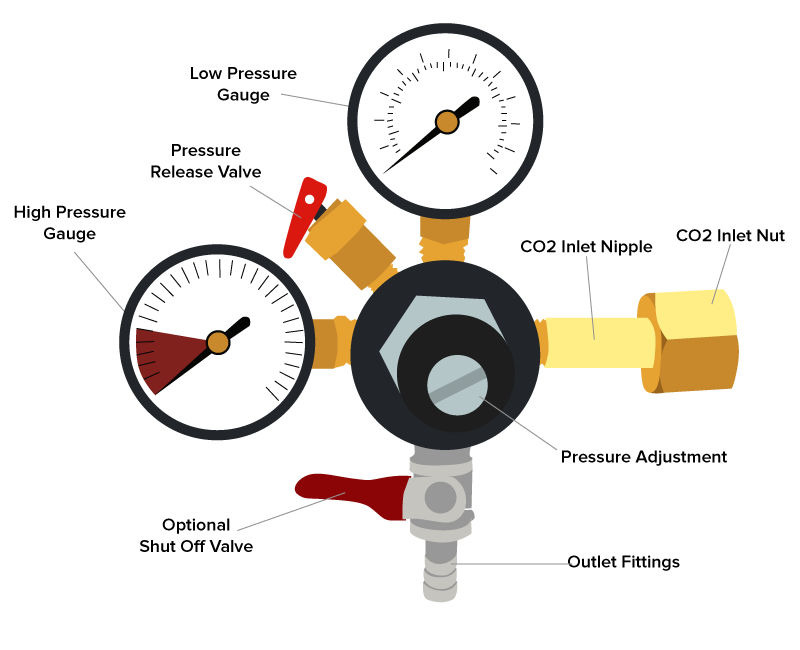

Parts of a Draft Beer Regulator

- Low pressure gauge: Measures the pressure of the gas going into your keg.

- High pressure gauge: Measures the amount of gas remaining in the tank.

- Shut off valve: Opens and closes the flow of gas from the tank to the regulator and keg. Flow is open when the lever is parallel to the gas line, and closed when perpendicular to the line.

- Pressure adjustment: Sets the level of pressure going to the keg. This may be adjusted by turning a screw or knob depending on the model of your regulator.

- Outlet fitting: Connects air line from keg coupler to the regulator.

- CO2 inlet: Connects regulator to gas tank. Use an air tank wrench to tighten or loosen the inlet nut.

- Pressure release valve: Pull to release gas from the system

Types of Draft Beer Regulators

CO2 Regulator

A primary CO2 regulator hooks up to your CO2 tank. In simple draft configurations, the air line then runs from the regulator to the keg coupler. If you are dispensing multiple kegs from one tank of gas, the airline might pass through a gas blender or secondary regulator before reaching the coupler.

Nitrogen Regulator

If you want to dispense Guinness or any other nitro beer, you’ll need a primary Nitrogen regulator. Like a primary CO2 regulator, it connects directly to the gas tank or cylinder to moderate its pressure. Unlike a CO2 regulator, it attaches to the tank by way of a female stem piece. A CO2 regulator will not properly attach to a Nitrogen tank. If you want to dispense a nitro beer without investing in a Nitrogen regulator, you can purchase a CO2 to nitrogen adapter piece instead.

Whether you are talking Nitrogen or CO2, primary regulators come in single-gauge and double-gauge models. Single-gauge regulators only have a low-pressure gauge, which measures from 0 to 60 PSI the output pressure of the gas being dispensed into the keg. Double-gauge regulators (shown above) have both a low-pressure gauge and a high pressure gauge, which measures from 0 to 3000 PSI the amount of CO2 or Nitrogen left in the tank. A high-pressure gauge is extremely helpful but not essential to draft beer dispensing.

Secondary Regulator

If you are dispensing two or more kegs from a single gas source, a secondary beer regulator may be required. That’s because different beers often call for different dispensing pressures to maintain the carbonation level prescribed by the brewer. Failure to adhere to the brewer’s recommendation is to risk changing the appearance, mouthfeel, and taste of a beer.

Distribution Bar

To dispense multiple kegs all at the same pressure, you‘ll need a distribution bar, which is basically a large splitter. The primary regulator determines the pressure of gas flowing through a distributor. A distribution bar does not allow you to adjust the pressure for each keg.

Troubleshooting Improper Dispensing Pressure

Most beers are dispensed somewhere in the range of 10 to 15 PSI. If you are pouring a nitro beer, that range increases to 30 to 40 PSI. For more information on how to properly set the pressure for your draft beer system consult our guide to Determining the Right Pressure for Your Draft Beer System as well as our 8 Answers to Frequently Asked Draft Beer CO2 Questions.

A dispensing pressure that’s too low will result in excessive foam as the gas dissolved in the beer comes out of solution. Eventually, the keg will dispense flat beer.

To correct the problem, make sure your regulator is set to the proper PSI. If it isn’t, turn the adjustment screw clockwise to raise the pressure to the prescribed level. Otherwise, you should make sure that your CO2 tank is on and not empty, and that the the air line is not obstructed. If all of those things check out and you are still getting foamy to flat beer, you may need to replace your regulator or gauge. Regulators do wear down with time and use. You will generally need to replace them every four to six years.

A too-high dispensing pressure will force additional gas into the beer, leaving you with foamy beer that comes quickly out of the faucet. If your beer is over-carbonated, the foam will appear tight with large bubbles.

If you encounter this problem, it’s easy to fix. Turn the adjustment screw counterclockwise to lower the pressure to the proper level and then draw a few foamy pitchers. You can also use your coupler’s relief valve to bleed out the extra pressure. These measures will force your system to balance itself out again.

If you’re having problems with pouring pints from your kegerator or draft beer system, then check out our tips for Troubleshooting Your Draft Beer System.

Tags:

Kegworks

Kegworks has been transforming hospitality spaces since 1998 with expertly crafted architectural metalwork and professional draft beer equipment, helping designers, architects, and bar professionals bring their visions to life.

Leave a Comment