Let’s break down how an air cooled draft beer system works and the parts you’ll need to install one.

The biggest challenge with any commercial draft beer system is keeping your product chilled as it flows from keg to tap. Beer that sits in draft lines can increase in temperature if the lines are not properly kept cool. This leads to an increased chance of beer pouring foamy, and promotes the growth of bacteria in your lines.

There are two industry standard methods for cooling lines in a long draw draft system: glycol cooled and air cooled. Glycol cooled draft systems are required for long draw draft systems that run longer than 25 feet, and use a glycol power pack to push a coolant through lines that are bundled with beer lines to keep them cool (known as a trunk line). If your long draw commercial draft beer system is less than 25 feet to travel from keg to tap (also known as a short draw system), then an air cooled draft system is a viable and less expensive alternative to using glycol.

What Is An Air Cooled Draft Beer System?

The method of forcing chilled air from keg to tap was the only way to chill your draft lines until the arrival of glycol. Despite its status as the O.G. when it comes to cooling, it is still a viable and less expensive option to glycol chilling for short draw draft systems.

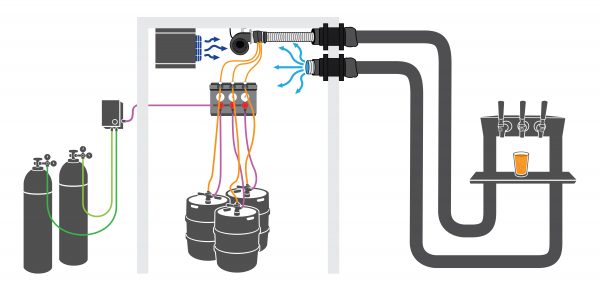

An air cooled (or forced air) draft system uses a forced air blower to push chilled air from your cooler through PVC blower tubing or duct containing your beer lines all the way to your tower. The tubing is wrapped with foam insulation to keep cold air from escaping. The cool air also helps keep the tower chilled before circulating back to the cooler.

Types of Air Cooled Draft Beer Systems

There are two types of air cooled draft systems: single-duct and double-duct.

Single-Duct System

A single duct system uses one conduit for transporting air to and from the draft tower. A larger duct, typically 4” in outer diameter (O.D.), holds two smaller ducts (2” & 3” O.D.) inside of it. The chilled air and beer lines travel through the smallest duct from the cooler to the tower while the spent air returns to the cooler via the larger inner duct. A single-duct system uses a single column draft beer tower or T-tower for dispensing. A baffle plate and air separator are installed just below the tower to help ensure proper air circulation. A single-duct air cooled system is recommended for draft runs of 15 feet or less. For example, if your cooler is in the room adjacent to your bar and you are just running lines through the wall between them to your taps.

Double-Duct System

The double-duct system uses two ducts to circulate chilled air to and from your cooler. The first duct carries beer lines and chilled air from the cooler to the tower. The air travels through a double pedestal draft tower (H-tower), wall mounted draft tower or under bar mounted draft tower with an air box, and then back to the cooler through a second duct. A double-duct air cooled system is used for draft runs of up to 25 feet.

Must Have Parts For Air Cooled Draft System

Forced Air Blower

The forced air blower is attached inside a walk-in cooler or refrigeration unit, adjacent to the source of the cold air. The blower sends air through a duct containing beer lines, which goes to the draft tower. The cold air keeps beer in the lines chilled as well as the draft tower.

Your forced air blower should be installed as close to the fan or vent inside your cooler as possible. It is important to remember that, just like any other motorized device, the blower does generate heat when it is running. Make sure your refrigeration unit can withstand the heat generated by your blower. Many units are designed to cool the exact dimensions of the walk-in cooler they are installed in. Your blower could place a strain on your refrigeration unit.

PVC Blower Tubing & Insulation

The PVC blower tubing creates the duct or conduit to carry your beer lines and cooled air. In a single-duct system a larger duct, typically 4” in outer diameter (O.D.), holds two smaller ducts (2 & 3” O.D.) inside of it. The chilled air and beer lines travel through the smallest duct from the cooler to the tower while the spent air returns to the cooler via the larger inner duct. Flexible aluminum tubing can also be used for this application.

Be sure to use foam insulation to keep the cooled air and beer lines cold. Foam insulation should be a half-inch larger than the tubing it covers. It is imperative that your tubing is well insulated because they are vulnerable to temperature changes in the outside environment.

Air Baffle & Separator

These parts are only required for single-duct systems. Feel free to skip over this part if you are building a double-duct one. The air baffle and air separator mount inside the base of the draft tower to help maintain air flow between the air coming to and from the cooler in a single-duct system. The separator connects to the mounting flange. The baffle fits inside the separator.

Insulated Elbow

The insulated elbow connector allows you to add a 90-degree turn to your air cooled duct. We do not recommend having more than two 90-degree bends in an air cooled draft system. The inclusion of a 90-degree bend through an elbow connector adds the equivalent of five feet of run to your system. A system with a 15 foot run with a 90 degree bend is equivalent to a 20 foot run.

Air Cooled Checklist

Now that you’ve learned what forced air draft systems are all about, let’s go over one more time what requirements you need to meet before going this route for your bar.

Does your draft system…

- Have a run of 25 feet or less that does not require more than two 90-degree turns?

- Have a refrigeration unit (cooler) that can handle a blower fan operating inside of it?

If you said yes to both of these questions, then you are ready to start building your air cooled draft system. If you’re looking for more guidance on building your commercial draft beer system, then reach out to KegWorks’ draft beer specialists for more information.

Tags:

Dave Buchanan

Dave Buchanan has been the Content Writer for Kegworks since June 2019. He has a fondness for craft beer that developed while working for a local beer distributor. Dave also worked for an area sports talk radio station for several years, and continues his broadcasting work as a motorsports announcer and indoor lacrosse reporter.

Leave a Comment