You’re tending your bar on a typically crowded night. You’ve been serving a steady flow of your establishment’s popular flight of draft beers, but you know that one or two brands gets the tap pull more commonly than the others. Don’t worry. You just checked the barrels. All kegs are full and heavy—no way you’ll be switching out kegs until the crowd begins to shrink. At least that’s what you think...

You’re tending your bar on a typically crowded night. You’ve been serving a steady flow of your establishment’s popular flight of draft beers, but you know that one or two brands gets the tap pull more commonly than the others. Don’t worry. You just checked the barrels. All kegs are full and heavy—no way you’ll be switching out kegs until the crowd begins to shrink. At least that’s what you think...

Then the crowd begins to grow, and the action picks up. Everyone on your service team is chasing orders, trying to keep up with the steady demands. Good for business? Absolutely. But what’s happening down in your beer cellar? You take what seems like your fiftieth request for two pints of your most popular IPA. The second pour is midway up the glass when…. PSHHHHHHT! There goes the foam. Kicked!

It’s disappointing for your patron when you return with only one beer, telling him, “Sorry, buddy, our keg’s kicked. I’ve got to go downstairs and change it over.” He’s thirsty. And he’s been waiting.

It doesn’t have to be this way. One way to maximize profit and performance of your draft system in the face of high demand is to implement a kegs in series system--that is, a system of chained or linked kegs of the same beer. A series of linked kegs means that you’ll have to get through all the kegs before beer stops flowing.

Before You Get Started

Before establishing a series of kegs, there are a few things to keep in mind:

- Make sure that you’re chaining kegs of a product that you turn over with regularity. To maintain freshness throughout all of your lines, you’ll want to be able to sell the whole run of kegs in about a week.

- You’ll also want to make sure that all of your kegs are kept at the optimal serving temperature before setting up the system. (We recommend 38° F.)

There are also some definitions you should know:

- The gas keg is the keg in the series that connects to your gas supply, be it CO², nitrogen, or a mix. It should be your freshest keg.

- The faucet keg is the keg connected to the faucet via beer line. It should be your oldest keg.

- Any kegs in the series between the gas keg and faucet keg are called intermediate kegs.

Kegs in Series Assembly

Below are general instructions for assembling a keg series of any size. But note that we don’t recommend exceeding 10 kegs in a series. Adhering to this maximum will help ensure proper rate of flow. And recall that you shouldn’t link more kegs that you can feasibly empty within a week.

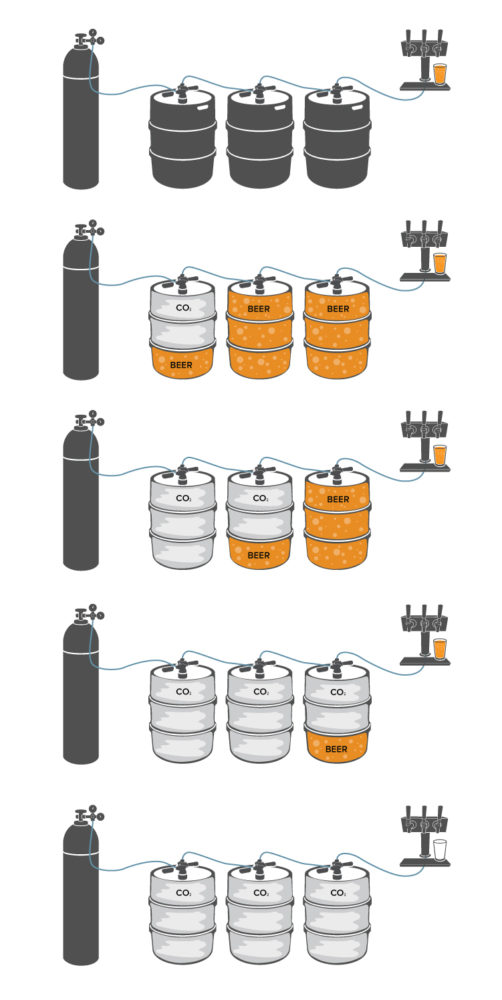

- It’s best to start with full kegs so you’re not running older beer through freshly tapped full kegs. Arrange them like you see in our illustration.

- The gas keg should be tapped with a standard coupler, while the intermediate and faucet kegs should have the Thomas valve removed from the gas side of each of of their couplers.

- Using jumper line, connect the beer outlet of the gas keg to CO² inlet on the closest intermediate keg. Connect any additional intermediate kegs the same way until you get to your faucet keg, which you will connect directly to your faucet.

- Note that restriction should be determined based on the distance from the faucet keg to the faucet.

You can see in the illustration that pressurized beer will travel from your gas keg to your intermediate keg(s) and onward into the faucet keg before finally dispensing out of your faucet.

Kegs in Series Rotation

Kegs in Series Rotation

As your rotation gets rolling and you start inserting new kegs in the series, it’s important to remember a few things:

- Any partial keg remaining should be moved to the gas keg position. This helps avoid large air pockets from forming in the series, which can lead to foaming and beer flow issues.

- The faucet keg should also be your oldest keg, as you’ll want this beer to dispense before the fresher ones. The next oldest keg should be the intermediate keg closest to the faucet keg, and so on toward the gas keg.

Once you get a keg series flowing properly, you can be reasonably sure that you won’t have to swap out empty kegs of your most popular beers in the middle of a busy shift. You’ll be continually serving up fresh product, your staff will be relieved, and your patrons will never have to wait for their favorite pint.

Have questions about assembling a keg series? Give one of our draft equipment specialists a call at 1.888.415.2803.

Leave a Comment